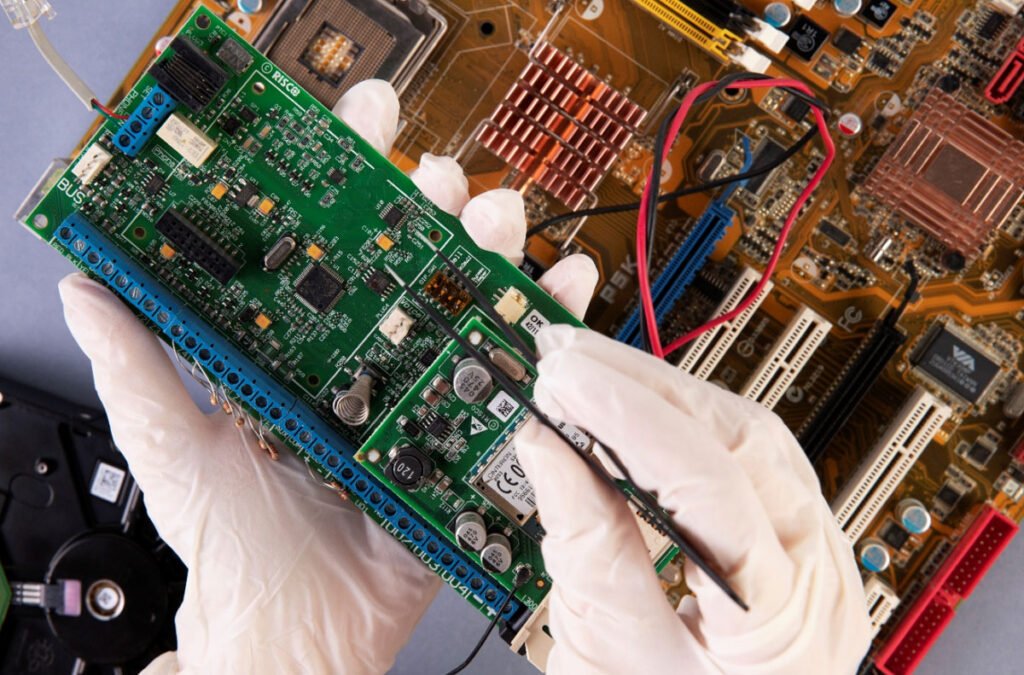

In modern electronics manufacturing, reliability is not optional—it is expected. Consumers, businesses, and industries depend on electronic products to perform consistently, often in demanding environments. While design and materials play important roles, the true measure of reliability lies in how thoroughly printed circuit boards (PCBs) are tested and inspected before reaching final assembly.

PCB testing and inspection act as the final safeguard against defects, failures, and performance issues. A well-tested PCB ensures that electronic devices function as intended, meet quality expectations, and maintain long-term durability. For manufacturers, working with PCB suppliers that prioritize rigorous testing is essential for protecting product quality and brand reputation.

This article explores the importance of PCB testing, common inspection methods, and how reliability-focused suppliers help manufacturers deliver dependable electronic products.

Table of Contents

ToggleThe Hidden Risks of Untested PCBs

Even minor PCB defects can lead to significant problems once products reach the market. Issues such as poor solder joints, short circuits, or signal integrity failures may not be visible during assembly but can cause malfunctions over time.

Common risks associated with inadequate PCB testing include:

- Intermittent electrical failures

- Reduced product lifespan

- Unexpected field returns

- Increased warranty and repair costs

Testing and inspection help identify these issues early, preventing costly downstream consequences.

The Purpose of PCB Testing in Manufacturing

PCB testing verifies that electrical connections function correctly and that the board meets design specifications. It ensures that current flows where intended and that no unintended paths exist.

Effective testing supports:

- Electrical continuity validation

- Detection of shorts and open circuits

- Verification of component placement

- Confirmation of functional performance

By validating these factors, manufacturers gain confidence that their products will operate reliably in real-world conditions.

Common PCB Inspection Techniques

Inspection methods focus on identifying physical and visual defects that could affect performance or reliability. These inspections are typically performed at multiple stages of production.

Visual Inspection

Visual inspection is the most basic method, involving manual or automated checks for visible defects such as misaligned components, damaged traces, or solder issues.

Automated Optical Inspection (AOI)

AOI systems use cameras and software to detect defects quickly and accurately. This method improves consistency and reduces the risk of human error.

X-Ray Inspection

X-ray inspection is used for complex assemblies where solder joints or internal layers are not visible. It is especially important for high-density and multi-layer PCBs.

These inspection techniques complement each other, creating a comprehensive quality control system.

Electrical Testing for Functional Assurance

Electrical testing ensures that the PCB performs as designed. This type of testing verifies connectivity, signal integrity, and overall functionality.

Common electrical tests include:

- Continuity testing

- Insulation resistance testing

- Functional circuit testing

Electrical testing helps confirm that the PCB can support reliable operation under expected conditions.

Testing as a Tool for Process Improvement

Beyond defect detection, PCB testing provides valuable feedback for improving manufacturing processes. Patterns in test failures can reveal underlying issues in materials, equipment, or workflows.

By analyzing test results, suppliers can:

- Refine production techniques

- Improve yield rates

- Enhance consistency across batches

This continuous improvement approach strengthens overall manufacturing reliability.

Why Manufacturers Prioritize Tested PCBs

Manufacturers rely on tested PCBs to minimize risk throughout the product lifecycle. A single defective board can compromise an entire system, making thorough testing essential.

Benefits of rigorous PCB testing include:

- Reduced product failures

- Improved customer satisfaction

- Lower long-term costs

- Stronger brand trust

This is why many manufacturers choose to work with reliability-focused partners like GlobalWell Printed Circuit Board Supplier when testing and inspection standards are a top priority.

Reliability in High-Demand Applications

Certain industries require exceptionally high reliability, where failures are not acceptable. In such cases, PCB testing becomes even more critical.

High-demand applications often require:

- Multiple inspection stages

- Enhanced electrical testing

- Strict documentation and traceability

Suppliers experienced in reliability assurance understand how to meet these heightened expectations.

The Role of Documentation and Traceability

Testing and inspection results are only valuable when properly documented. Traceability allows manufacturers to track production history and address issues efficiently if problems arise.

Strong documentation supports:

- Quality audits

- Root cause analysis

- Regulatory compliance

- Continuous improvement efforts

Suppliers with robust documentation practices demonstrate professionalism and accountability.

Balancing Speed and Accuracy in Testing

In fast-paced manufacturing environments, there is often pressure to move quickly. However, rushing testing processes can lead to overlooked defects.

Professional PCB suppliers balance speed with accuracy by:

- Using automated inspection systems

- Standardizing testing procedures

- Maintaining skilled quality teams

This balance ensures efficiency without compromising reliability.

Digital Transparency in Quality Assurance

In today’s connected world, manufacturers often assess suppliers based on available information. Platforms such as globalwellpcba.com provide insight into how PCB suppliers communicate their quality control practices and manufacturing capabilities.

A transparent digital presence supports informed decision-making and builds trust before formal engagement.

Preparing for Increasing Reliability Expectations

As electronics become more integrated into critical systems, reliability expectations will continue to rise. PCB suppliers must invest in advanced testing technologies and skilled personnel to keep pace.

Manufacturers partnering with experienced providers like GlobalWell Printed Circuit Board Supplier are better positioned to meet future reliability challenges with confidence.

Conclusion

PCB testing and inspection are essential pillars of reliable electronics manufacturing. By identifying defects early, validating performance, and supporting continuous improvement, thorough testing protects both manufacturers and end users.

For companies seeking long-term success, partnering with PCB suppliers that prioritize rigorous testing and inspection is a strategic decision—one that ensures product reliability, customer satisfaction, and lasting brand credibility.