In case you are planning to expand your custom printing company, you will be in a better position to realize the distinction between UV DTF printer and DTF printing.

Both systems assist you to come up with quality designs that are enjoyed by the customers. All of them embrace varying material and texture.

It is on learning how they work that you will be able to select the method that fits within your product line and long term business plans.

Most of the new printers are not sure of themselves in the beginning but the two processes will be so easy after clear explanations on the basics.

Table of Contents

ToggleWhat DTF Printing Means

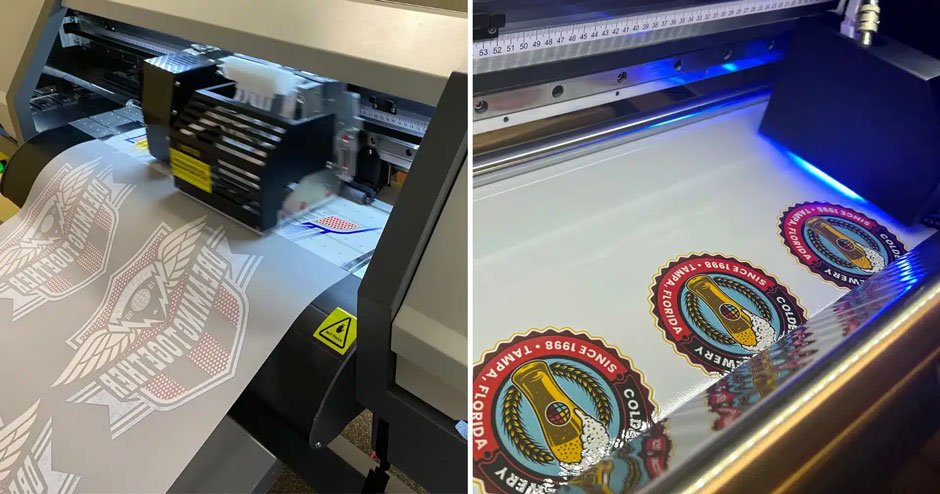

DTF printing means Direct to Film printing. This process begins by printing your design on a special film using water based ink. The design is added to a powder adhesive. By heating, the powder fuses and a strong bond is established.

Once the design is made, you put the film on the cloth and press it with a heat press. This causes the piece of art to stick well to the material. DTF printing is best used on cotton, polyester, blends, and a wide range of other soft fabric.

The end result is a print that is smooth, flexible and comfortable to wear on a daily basis. This is the reason why it is used in several clothing brands in T shirts, hoodies, tote bags, and hats.

What UV DTF Printing Means

UV DTF printing uses a different type of technology. A UV DTF printer places UV curable ink onto an A film. The ink dries instantly when exposed to ultraviolet light.

After printing, the film is combined with a B film that prepares the design for transfer. You apply the finished transfer by peeling and pressing it onto the surface.

You do not need heat for this step. This can save you time and will not require additional equipment. UV DTF printing is effective on hard material like metal, acrylic, plastic, ceramic, glass and coated wood.

The last design seems to be glossy, elevated, and very tough. Many businesses choose this method because it gives products a premium look.

Key Differences Between UV DTF and DTF Printing

The main difference between both printing systems comes from the ink. DTF uses water based ink that blends into fabric.

UV DTF uses UV curable ink that forms a firm and raised layer. This leads to two different results. The equipment available at dtflinko.com offers dependable performance for beginners and professionals.

DTF printing is ideal for clothing because it remains soft. UV DTF printing is ideal for hard objects because the printed surface becomes strong and shiny.

Material compatibility also separates the two methods. DTF works best on textiles. UV DTF works best on smooth and rigid surfaces.

The application method also differs. DTF printing requires a heat press to melt the adhesive. UV DTF printing does not require heat, which helps you work faster.

The final texture shows a clear difference as well. DTF prints feel soft and natural on fabric. UV DTF prints are tough, smooth, and slightly protruded.

This causes them to be visually distinct on products like phone cases, drinking ware and decorative accessories.

Benefits of DTF Printing

- DTF printing supports apparel and wearable products.

- The prints stay bright after many washes, and the soft feeling increases comfort.

- Detailed artwork also appears clean and accurate with DTF printing.

- This allows you to create professional designs even when you operate a small studio.

- The workflow is beginner friendly.

- With basic training, you can learn how to use the system and start producing custom clothing quickly.

Customers enjoy the comfort and durability of DTF prints, which helps increase repeat sales.

Benefits of UV DTF Printing

- UV DTF printing supports personalization for hard goods.

- The prints resist scratching, fading, and water exposure.

- This makes them ideal for items that customers use daily.

- The glossy and raised texture gives your products a premium appearance that attracts attention.

- Many shops select UV DTF printing because it helps them offer unique gifts, event items, and branded merchandise.

- The instant curing process also improves production speed since the ink dries as it prints.

- This helps you handle large orders without delays.

As long as you are using a good UV DTF printer, you will be designing graphics that can be long lasting.

What is the Right Method to Select?

It will be a choice based on your product objectives. If you want to focus on clothing, DTF printing will support your needs with soft and flexible results.

Many print shops use both methods because each one supports different markets. This combination helps you serve more customers and expand your catalog.

Choosing the Right UV DTF Printer

If you want smooth and consistent UV DTF results, choosing a reliable machine is important. A high-quality UV DTF printer gives you stable color output, clear detail, and strong UV curing.

When you select suppliers through dtflinko.com, you gain access to trustworthy machines and helpful support.

You can also explore product guides at dtflinko.com to improve your workflow. This resource will make you invest in a powerful machine capable of making your production faster and less wasteful.

Final Thoughts

Both DTF printing and UV DTF printing enable you to develop your business in various ways. UV DTF printing is capable of customization of hard surfaces with high-end appearance, whereas DTF printing is capable of customization of soft and wearable products with a smooth surface.

Once you know the advantages of any technique, you will be able to align them with your objectives and develop products that can be trusted by customers.

Having the appropriate equipment, particularly a reliable UV DTF printer, with either a reliable supplier such as dtflinko.com, you could provide appealing designs, and establish a robust printing company.